Products

A Fan is a machine utilizing thin rotating rigid vanes, which is driven by a prime mover, which causes a compressible fluid to move.

The main function of an BOILER Fan is to supply a huge flow of air or gas to the various processes in the industries. They are equipped with backward curved blades and wheels to drive a current of air or gas from one point to another with certain specifications and to suit different applications. We manufacture and provide customized selection and design to suit each application. This is achieved by rotation of blades, connected to a hub and shaft, and driven by a motor.

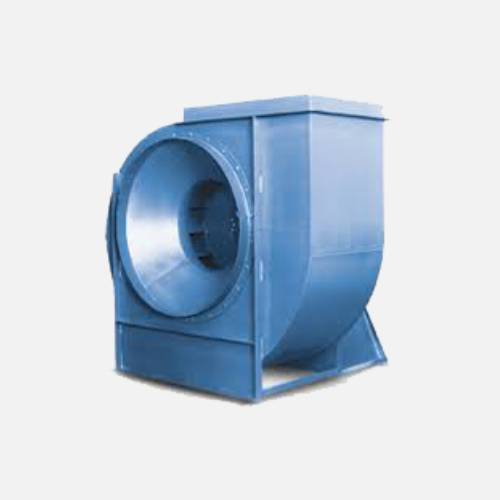

CENTRIFUGAL BLOWERS

We manufacture Backward curved, Radial Centrifugal Blowers with SINGLE INLET, SINGLE WIDTH (SISW) type and DOUBLE INLET, DOUBLE WIDTH (DIDW) types.

Manufactured to suit various specifications and applications these are designed perfect with robust construction and in line with quality standards.

| Type | Centrifugal |

| Impeller | Backward curved, Radial |

Features of Cenrifugal Blowers

Material Of Construction

Impeller Type

Drive

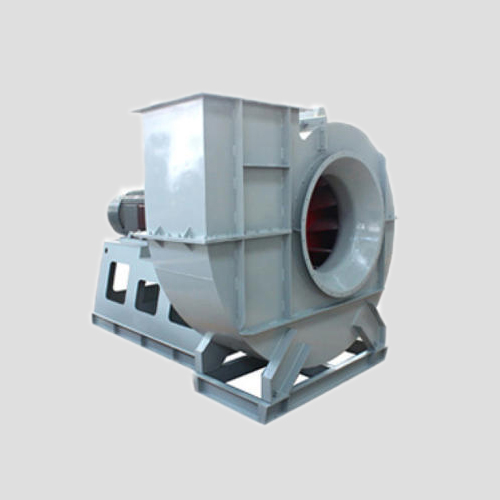

ID / FD AND PA Fans (INDUCED DRAFT, FORCED DRAFT AND PRIMARY AIR Fans)

ID Fan (INDUCED DRAFD Fan) & FD Fan (FORCED DRAFD Fans)

ID Fans (induced draught system) and FD Fans (forced draught system) is used in steam power plants generating electricity from fossil fuels. They need to produce draught, a gradient of pressure to push burnt gases out of the boiler and to suck fresh air in between the boiler and the chimney and to improve the efficiency of the power plant.

In ID system, the Fan is located at the base of chimney, thus maintaining high pressure to drive out the gases through the chimney and a low pressure in boiler to suck in fresh air and in successive accessories.

In FD system, the Fan is located at air inlet of the boiler. Hence it pushes high pressure fresh air into the boiler and the pressure decreases through the accessories upto the chimney.

Although the FD system has quite a number of advantages over the ID system, a combination of both, known as 'Balanced Draught System' is used to combine the advantages of both. In this a Fan is installed at both the above mentioned positions.

PA Fan (PRIMARY AIR Fan)

The main function of the Primary air Fan or PA Fan is to carry the pulverized coal to the furnace as fuel for combustion. This process is used to create the steam that is the primary process in the thermal power plant. In power plants, the PA Fans supply air for conveying of the pulverized coal from coal mills to the furnace area. These primary air Fans produce a high pressure to push the coal and air mixture through pulverizer into the furnace. The most common configuration of the draught Fans used as a PA Fan is the backward curved Centrifugal Fan. In power plants the PA Fans play an important role in supplying air necessary for fuel combustion and in the maintenance of furnace temperature.

Centrifugal blowers are routinely used for applications such as dust control, combustion air supplies, on cooling, drying systems, for fluid bed aerators with air conveyor systems etc.

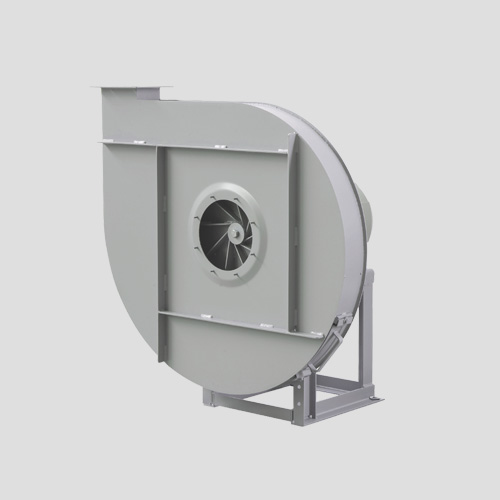

Limit Load Fans (LL and LD)

Limit load blower is designed for varied application in the field of air conditioning, industrial ventilation, humidification, heating and evaporative air cooling. This blower is provided with a medium speed impeller having double curved backward discharge tip blades and stationery directional inlet vanes for quite operation and maximum efficiency. The blower is available in single inlet and double inlet construction.

These are provided with a medium speed impeller having Double curved Backward discharge tip blades and stationary directional (Guide Vanes) inlet vanes.

‘LL’ and ‘LD’ impellers have deep wide blades which are more efficient and of extra rigid nature because of their double curved feature. Due to their extra width and full open tip, the operational noise level is quiet low compared to other designs of Backward curved Fans.

The following Fan arrangements are those generally used. Fans are designated as CLOCKWISE or ANTICLOCKWISE, if when facing the drive end shaft the direction of wheel rotation is clockwise or anti-clockwise. The discharge orientation of a Fan is determined by the direction of the line of air discharge and it’s relation to the Fan shaft for every complete 90 Deg of rotation. All other discharge orientations are intermediate discharges and are indicated as ANGULAR DISCHARGES.

AXIAL FLOW Fans

We offer Axial Flow Fans, Tube Axial Fans, Axial Fans for the following application

VANE AXIAL Fan

Vane axial Fans are similar to tube axials, but with addition of guide vanes that improve efficiency by directing and straightening the flow. As a result, they have a higher static pressure with less dependence on the duct static pressure. Such Fans are used generally for pressures upto 500 mmWC. Vaneaxials are typically the most energy-efficient Fans available and should be used whenever possible.

Propeller Fans usually run at low speeds and moderate temperatures. They experience a large change in airflow with small changes in static pressure. They handle large volumes of air at low pressure or free delivery. Propeller Fans are often used indoors as exhaust Fans. Outdoor applications include air-cooled condensers and cooling towers. Efficiency is low, approximately 50% or less.

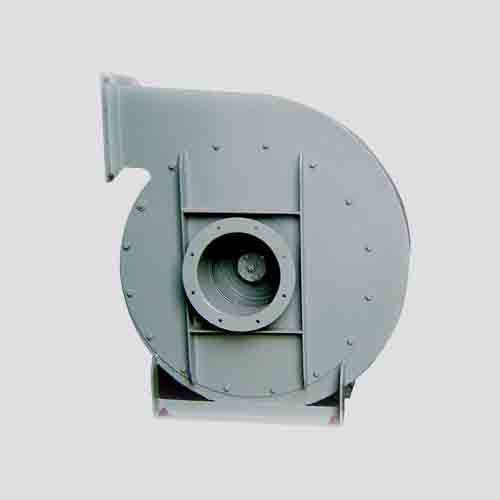

HIGH PRESSURE Fans

These Fans have a high-pressure range and perfect for usage in pad cooling, air filters, and agricultural drying applications as per the industry specific standards.

DUST COLLECTORS

We provide Dust Collectors of Pulsejet type and Cyclone type for Pulsejet Bag Filters with high efficiency and design.

The Bags are of Polyester Non-woven Needle felt Bags using high quality material to ensure utmost efficiency and high durability.

UNIT DUST COLLECTORS

We offer Unit Dust Collectors portable type, with hose, moving platform wheels that can be moved over to any location, fitted and used.

PULSE JET TYPE DUST COLLECTORS

Pulse jet Type Dust Collectors are used in various types of industries as Pollution Control System / Equipments as a total Unit.

With thorough knowledge and technical knowhow we design as per the customer needs and completely in line with the specific industry needs or requirements.

INDUSTRIAL Fans / BLOWERS / AIR POLLUTION CONTROL EQUIPMENTS SYSTEMS

A Fan is a machine utilizing thin rotating rigid vanes, which is driven by a prime mover, which causes a compressible fluid to move.

Objective

Fans and Blowers provide air for Ventilation and Industrial process requirements.

Fan and Blower selection depends on the Volume Flow rate, Pressure, type of material handled, space limitations etc. Fans fall into two general categories namely: Centrifugal Flow and Axial Flow.

Divine Enterprises Located At Chennai And Established In The Year 2016, Manufacturers Of Industrial Fans, Blowers, Air Pollution Control Equipments, Systems. Though We Are A Newly Registered Unit, Our Engineers Are Technically Strong Having More Than Two Decades Of Experience In This Field. With A Thorough And Well Equipped Technical Expertise And Advanced Engineering Skills, We Assure To Give The Best Solution And Equipments To Meet Your Requirements.